Oil coolers used in hydraulic system

Other fields of soradiator are covered. Because of its professional production capacity, soradiator produces a wide range of products. Includes small oil coolers used in hydraulic systems. This product has the characteristics of small size and high pressure resistance. Every detail shows the siradiator's ultra-high production process.

Small oil coolers used in hydraulic systems are compact heat exchangers designed to remove excess heat from hydraulic fluid. They typically consist of a series of metal tubes or plates that provide a large surface area for efficient heat transfer. The hydraulic fluid flows through these tubes or plates, while a cooling medium, such as air or water, passes over the external surface to dissipate the heat.

These oil coolers are usually equipped with fins or turbulators on the internal surfaces of the tubes or plates to enhance heat transfer. Fins increase the surface area available for heat exchange, while turbulators disrupt the flow of fluid, promoting better mixing and heat transfer.

Small oil coolers are often integrated into the hydraulic system's circuit, either as standalone units or as part of the reservoir or heat exchanger assembly. They help maintain optimal operating temperatures by preventing the hydraulic fluid from overheating, which can lead to reduced system performance, component wear, and potential damage.

Some small oil coolers may also include additional features, such as bypass valves or temperature sensors, to regulate the flow of fluid or monitor the operating temperature. These coolers come in various sizes and configurations to suit different hydraulic system requirements, offering efficient cooling in a compact and space-saving design.

For other custom radiators, soradiator has its own machining workshop, which can fully meet customer customization needs. It can be fully customized according to the environment, pressure, length, nozzle, ventilation volume, flow rate, shock resistance, installation size, protective shield, etc. required by customers.

At the same time, it can also produce radiators for agricultural and forestry machinery. This kind of radiator has the characteristics of multi-functional integration. The radiator is water-cooled on one side and oil-cooled on the other. While ensuring the efficacy, it greatly compresses the space.

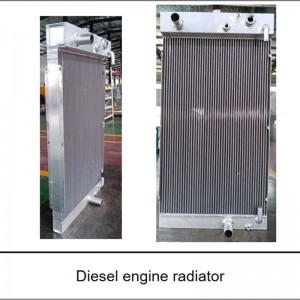

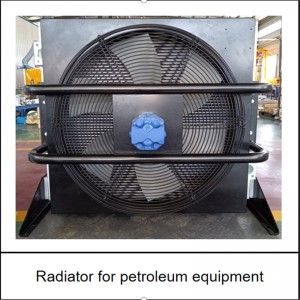

There are also radiators used in diesel engines. Radiators used in petroleum equipment, other radiators, etc.

Which involves soradiator's excellent argon arc welding process. Every soradiator welder has excellent manual argon welding skills accumulated for more than ten years. It can ensure the welding quality and appearance to the greatest extent. For high-pressure products, the soradiator adopts the technology of core chamfering + internal penetration of welding + two-pass welding at the same time. This welding management standard can ensure the welding pressure quality of products. The first pass rate of the gas tightness test of argon welding remains above 92%.

Developed based on the market-leading technological prowess, diverse Cooling Modules for construction equipments have been steadily adopted by customers with the market-proven quality.All-in-one Cooling Module enables smooth airflows with high thermal-exchanging performance and durability due to the combination of Bar & Plates.

The heat exchangers are developed in materials including aluminum and coopers, for special working conditions. Agricultural Cooling Modules are also developed with combination of Bar & Plate.