2022 Latest Design Aftermarket Radiator - Wind Power Generation And Welding Technology – Shuangfeng

2022 Latest Design Aftermarket Radiator - Wind Power Generation And Welding Technology – Shuangfeng Detail:

Wind power generation occupies an important share in the new energy sector. The heat exchanger plays an important role in the whole wind turbine. Heat exchangers provide cooling for generators, converters and gearboxes. Due to the particularity of installation environment and installation structure of wind power generation equipment, it is necessary to have strong requirements for long-term stable operation of heat exchanger.

Soradiator takes all possible risks into consideration from the beginning of design for products applied in the wind power field. For example, the corrosion of rainwater, the blockage of wind and sand, and so on. After decades of development, through various performance tests and customer feedback, continuous improvement of design and production process. So that the company’s products can meet the requirements of wind power customers.

Soradiator uses the best vacuum brazing furnace in the industry in the welding process. The vacuum brazing furnace is electromagnetic heated by diffusion pump. The brazing process can be controlled automatically or manually. At the same time has the function of program memory, alarm and so on. The ultimate vacuum degree of the vacuum furnace can reach 6.0*10-4Pa. Therefore, the brazing qualified rate and brazing strength of the product is greatly improved. In the process of entering the furnace, Soradiator adopts the industry’s original double bracket type furnace way to improve the temperature uniformity of products in the furnace. This way can increase the amount of furnace, while reducing energy consumption. The unique production process can ensure that the single pass rate of core brazing has been maintained at more than 98%.

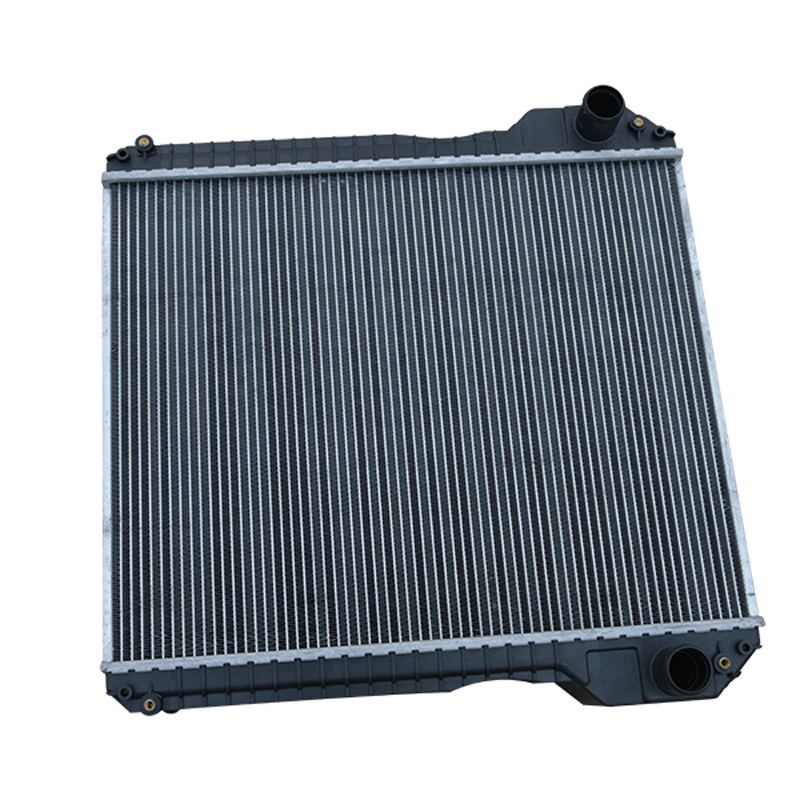

Cooling Modules, produced by processing with high purity aluminum, a new material, have successfully satisfied market demands of high performance and less environmental impacts for regulatory compliance. We have demonstrated our R&D competences by diversifying the components depending on user environments and thus providing our Cooling Modules in an on-demand manner.

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation is our business philosophy which is constantly observed and pursued by our company for 2022 Latest Design Aftermarket Radiator - Wind Power Generation And Welding Technology – Shuangfeng, The product will supply to all over the world, such as: Adelaide, Florida, India, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!