Factory making Forklift Oil Cooler - Railway Locomotives And Assembly Technology – Shuangfeng

Factory making Forklift Oil Cooler - Railway Locomotives And Assembly Technology – Shuangfeng Detail:

With the demand of rapid development of railway industry, electric locomotive has made great progress. As the cooling of electric locomotive heating components of the cooler, both from the structure and performance of the rapid development and put forward higher requirements.

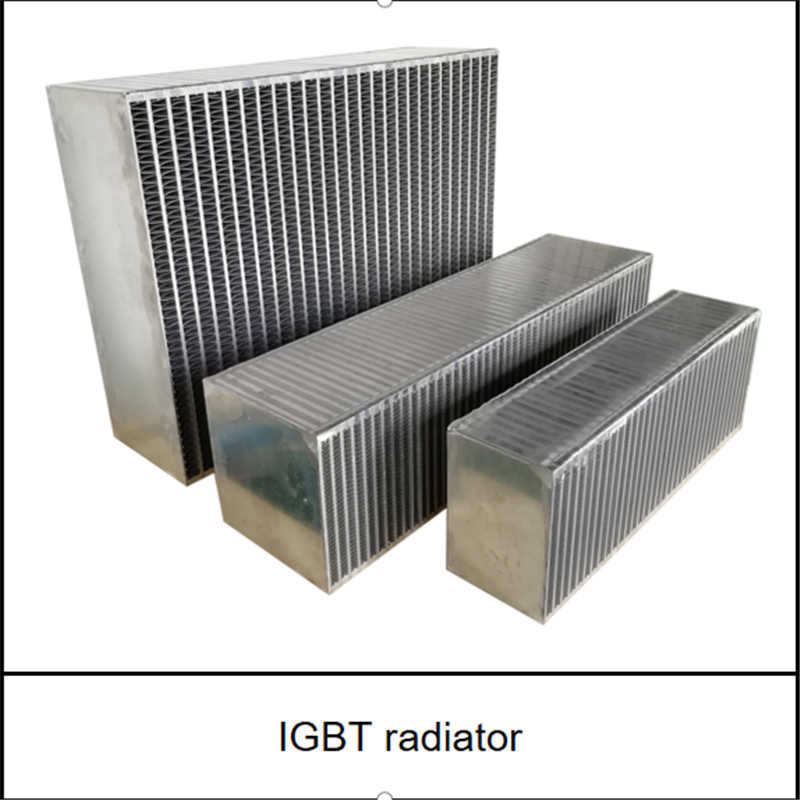

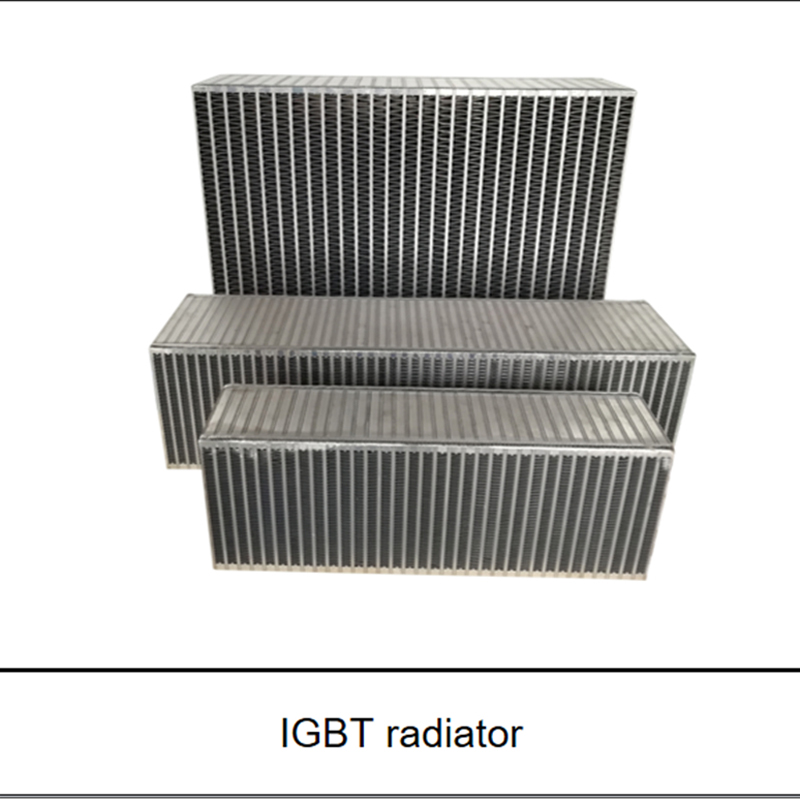

Soradiator has designed and developed aluminum radiators with compact structure, excellent performance and high reliability to meet the market demand. Soradiator was designed with this potential risk in mind. Such as vibration, corrosion and dust clogging resulting in reduced heat transfer efficiency. At the same time, according to the matching calculation of the fan characteristic curve of the whole cooling system and the fluid resistance characteristic curve of the cooler, the performance of the ventilation system and the oil and water system is optimized under the premise of ensuring the cooling capacity of the cooler.

In order to meet the core size and accuracy requirements, Soradiator has designed, developed, manufactured and put into production the high-precision plate-fin core assembly machine. This core assembly machine has applied for and passed the national patent certification. The assembly machine maximally guarantees the planarity of the five planes of the core, the perpendicularity and parallelism between the six planes. Compared with other manufacturers, the assembly machine can only ensure the flatness of two or three faces. Soradiator’s assembly process is largely ahead of industry standards. After the core assembly is completed, it can be packaged in one time. No need to beat during plastic surgery.

Soradiator’s own design and development of the spring fixture, the spring fixture through the national patent certification, every little detail is to further ensure the size, perpendicularity, flatness, parallelism and appearance of the core. At the same time, the brazing strength of core is improved.

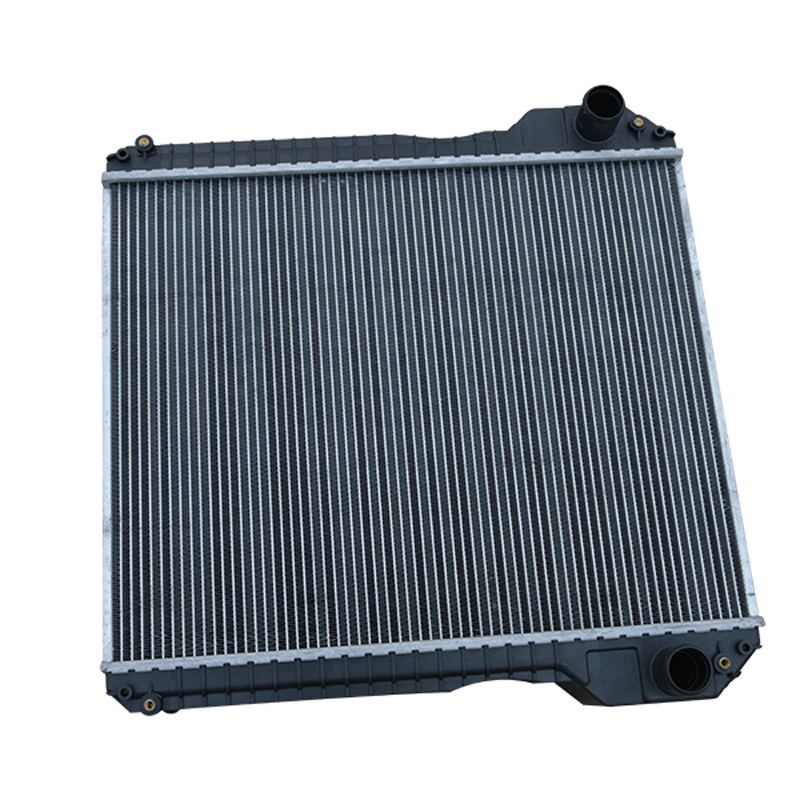

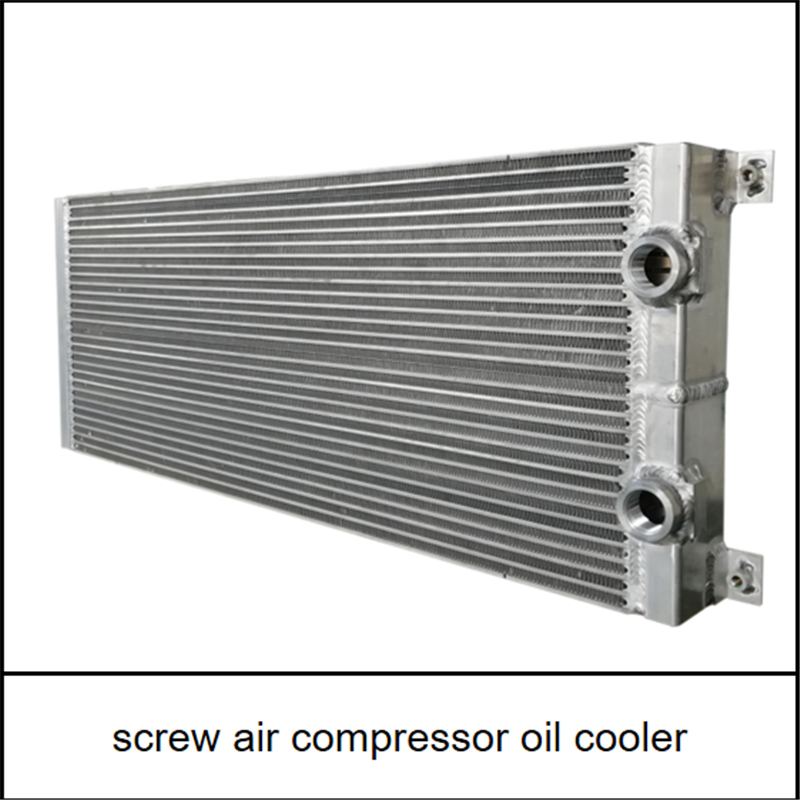

Product detail pictures:

Related Product Guide:

Good quality comes to start with; service is foremost; organization is cooperation is our enterprise philosophy which is regularly observed and pursued by our firm for Factory making Forklift Oil Cooler - Railway Locomotives And Assembly Technology – Shuangfeng, The product will supply to all over the world, such as: Burundi, Pakistan, Turkey, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

A good manufacturers, we have cooperated twice, good quality and good service attitude.